Additives Agents for Extruded Expandable Polystyrene

Description

In EPS production, optimum cell nucleation is key to superior finished product properties and performance. For over 40 years, NuCera polymers have provided the full range of advantages required to produce the world’s finest EPS industry.

Applications

- Improved density potential

- Faster prepuff maturation

- Better foam strength at the required density

- Faster mold cooling time

- Improved molding fusion

NuCera POLYWAX™ polyethylenes are fully saturated homopolymers of ethylene that exhibit a high degree of linearity and crystallinity. These synthetic waxes have narrow molecular weight distributions with a typical polydisperity (Mw/Mn) of 1.08. In application, POLYWAX polyethylenes exhibit sharp melting point, fast recrystallization, low melt viscosity, excellent heat stability and resistance to chemical attack.

When used in EPS production, POLYWAX polyethylenes promote the formation of small, uniformly sized cells, providing better surface finish and lower density of the final product. During the forming process, POLYWAX polyethylenes also perform as a mold release agent, reducing waste and improving cycle times

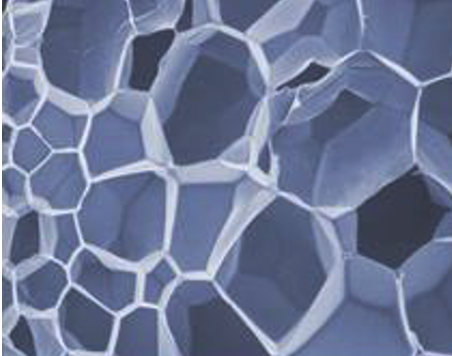

| The unique physical properties of POLYWAX polyethylenes… | …promote outstanding EPS products with excellent cell structure |

|---|---|

| Narrow molecular weight distribution | Improved cell uniformity – Narrower cell size distribution- Smaller cell size at the required concentration |

| High crystallinity | More blowing agent at the nucleating site – Consistent cell size |

What makes POLYWAX polyethylenes The Most Effective Nucleating Agents?

- Dissolve completely prior to significant polymerization

- Provide a critically sized nucleation site in the polystyrene matrix

- Serve as a gathering site for blowing agent

- Remain solid at expansion temperatures

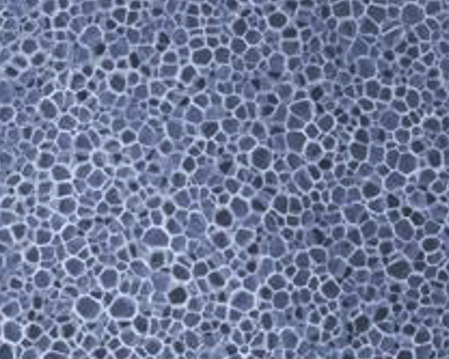

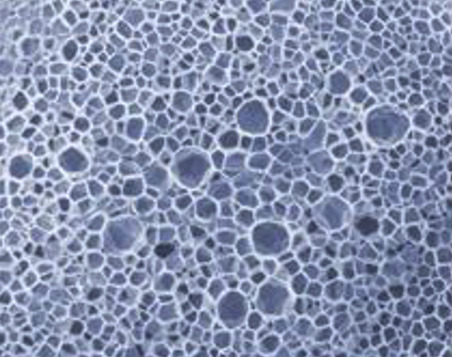

Effect on EPS Cell Structure

The photos below are of EPS beads, taken with a Scanning Electron Microscope (SEM), at 50X magnification. Note the development of small uniform cells when POLYWAX™ polyethylene is used as the nucleant.

No nucleant

2000 ppm POLYWAX™ 1000 polyethylene

2000 ppm competitive nucleant

Typical Properties

The choice of nucleant depends on EPS manufacturing processing conditions. Industry-standard grades are listed below, however, other grades of varying molecular weight are available to meet the needs of your specific production processes.

| Product / Test Method | Melt Point °C / ASTM D-127 | Viscosity cP @ 149 °C / ASTM D-3236 | Penetration dmm @ 25°C / ASTM- D1321 |

|---|---|---|---|

| POLYWAX™ 850 polyethylene | 107 | 10 | 1.0 |

| POLYWAX™ 1000 polyethylene | 113 | 15 | 1.0 |

| POLYWAX™ 2000 polyethylene | 126 | 55 | 0.5 |

Recommended Applications And Use Levels

Product Form

In addition to molecular weight, the product form can also impact the effectiveness of the nucleant in the EPS process.

POLYWAX polyethylenes are available in three physical forms:

- Prills – average particle size of 3 mm

- Mini prills – average particle size of 1 mm

- Micronized– certain grades are available in a micronized form